Lightweight refractory linings: a key to greater energy efficiency and lower emissions in the forging industry

Lowering pollutant emissions, optimizing energy consumption – like many other industrial sectors, the steel and metal industry faces the challenge of reducing both its energy use and environmental impact. Refractory linings are a decisive factor in the performance and energy footprint of high-temperature furnaces. The internationally operating refractory manufacturer RATH is increasingly focusing on lightweight refractory linings – including a newly developed, non-classified polycrystalline high-temperature insulation wool that has already demonstrated strong performance in the steel and metal industry.

Non-classified polycrystalline high-temperature wool: maximum service life and highly efficient thermal insulation

Innovative high-temperature wool products are playing an increasingly important role in lightweight refractory linings. Driven by a longstanding commitment to innovation, RATH has consistently led the advancement of high-temperature insulation materials through intensive in-house research and development. Among the latest innovations is a product that provides optimal support for the steel and metal industry when it comes to meeting both economic and environmental challenges: ALTRA® 1500C – a further development of the proven polycrystalline wool of the ALTRA® brand and the latest all-rounder in the series.

“With ALTRA® 1500C, RATH has developed a genuine alternative to other high-temperature wool products: it offers all the advantages of polycrystalline fibers, but is more cost-effective,” explains Richard Jäger.

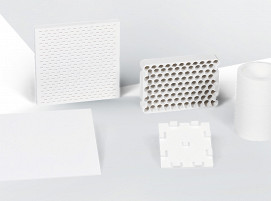

This newly developed, non-classified polycrystalline high-temperature insulation wool is optimized for use at temperatures up to 1500 °C and is available in both blanket and module form.

“In addition to its excellent cost-efficiency, its standout benefits include maximum service life and outstanding thermal insulation performance,” he adds.

Moreover, ALTRA® 1500C is fully compatible with other proven grades in the ALTRA® family – ALTRA® 72, for applications involving exceptionally high temperatures, and ALTRA® 97, when high chemical resistance is required.

ALTRA® 1500C: Successful application in steel and metal companies

ALTRA® 1500C opens up new possibilities for the steel and metal industry. Thanks to its carefully engineered physical properties, this high-temperature wool offers excellent energy efficiency and serves as an ideal complement to commonly used refractory products such as bricks and castables. ALTRA® 1500C is especially well suited for applications involving rapid heating and cooling cycles and is available in various densities and dimensions.

ALTRA® 1500C has already proven its value in the steel and metal industry through its successful use at several companies in Germany and Austria, where it has been applied in a variety of furnace types, including bogie hearth forging furnaces, chamber forging furnaces, rolling mill furnaces, and walking beam or rotary hearth furnaces. The lightweight yet highly durable ALTRA® 1500C modules, which are easy to handle and install, were successfully used, for example, in the delivery of the ceiling of a chamber forging furnace.